How to Fix a Blurry Barcode and Improve Scan Accuracy

A blurry barcode can cause scan errors, slow down operations, and lead to frustrating delays.

Smudged prints, torn barcodes that just won’t scan, sneaky curved surfaces that need some serious printing precision, packaging issues, with its see-through films and flashy metallic inks, the list of issues goes on and on.

But fear not, we’re here to walk you through these common barcode issues and then give you some practical fixes to keep your daily operations smooth.

7 Main Causes of Blurry Barcodes

- Poor barcode quality

- Ripped or torn barcodes

- Small barcode size

- Dirty or worn barcodes

- Printing errors

- Environmental factors

- Scanner or printer issues

Let’s walk through each and how you can fix them.

Poor Barcode Quality

The efficacy of barcode scanning is heavily dependent on the quality of the printed barcode. Low contrast between the bars and spaces can make it challenging for scanners to differentiate and decode the information accurately.

Factors contributing to poor quality include inadequate printing techniques, use of low-resolution printers, or inappropriate label materials. Ensuring high print quality with sufficient contrast and clarity is essential to maintain optimal scanning performance.

Ripped or Torn Barcodes

Physical damage such as rips or tears can significantly hinder a barcode’s readability. For 1D barcodes, horizontal damage may still allow for partial scanning if the remaining portion is intact.

However, vertical tears disrupt the entire data sequence, rendering the barcode unreadable. Implementing protective measures, such as using durable materials or applying clear laminates, can help preserve barcode integrity during handling and transportation.

Small Barcode Size

Compact barcodes pose scanning challenges due to their reduced dimensions. Smaller barcodes require scanners to be positioned closer and demand higher precision during scanning.

Additionally, printing tiny barcodes necessitates high-resolution printers to maintain clarity and prevent blurring. Ensuring that the barcode size aligns with the scanner’s capabilities and the printing technology used is crucial for reliable scanning.

Dirty or Worn Barcodes

Accumulation of dirt, exposure to moisture, or general wear can obscure barcode elements, leading to scanning difficulties.

Smudges or scratches can alter the appearance of bars and spaces, causing misreads or no-reads. Regular maintenance, such as cleaning barcode surfaces and using protective coatings, can mitigate these issues and prolong the barcode’s usability.

Printing Errors

Errors during the printing process, such as misalignment, ink smudging, or insufficient ink density, can produce defective barcodes.

These defects may result in barcodes with missing or merged bars, making them challenging for scanners to interpret.

Utilizing high-quality printers, regularly calibrating printing equipment, and conducting quality checks can prevent such errors and ensure barcode reliability.

Environmental Factors

External conditions like poor lighting, extreme temperatures, or reflective surfaces can adversely affect barcode scanning.

External elements impact durability:

- Heat makes thermal prints turn black

- Cold causes cracking and peeling

- Moisture smears the patterns

- Sun exposure leads to fading

- Chemicals break down materials

For instance, glare from overhead lights can create reflections that interfere with scanner readings. Positioning barcodes away from direct light sources and using matte label finishes can help reduce environmental scanning issues.

Scanner or Printer Issues

Malfunctions or misconfigurations in scanning devices or printers can lead to barcode readability problems. Dirty scanner lenses, outdated firmware, or incompatible settings may prevent accurate scanning.

Low DPI settings yield fuzzy patterns that devices struggle to read. Each use case needs specific DPI:

- 203 DPI: Basic barcode applications

- 300 DPI: Compact barcode printing

- 600 DPI: Maximum clarity for miniature codes

Regular maintenance of equipment, timely software updates, and ensuring compatibility between devices and barcode types are essential practices to maintain efficient scanning operations.

TLDR: Print output quality, surrounding conditions, plus regular use degrade barcode readability. Fixes involve calibrating equipment, selecting appropriate materials, plus protective steps.

How to Fix a Blurry Barcode for Each Issue

1. Poor Barcode Quality

To fix poor barcode quality, start by ensuring your barcode is generated using a high-resolution setting, ideally 300 DPI or higher.

Avoid compressing barcode images, especially in lossy formats like JPEG—use PNG or TIFF instead for lossless clarity.

Additionally, choose a barcode symbology appropriate for the data size; trying to squeeze too much into a small space can reduce scan accuracy. If you’re embedding barcodes into documents, make sure your document generator supports vector-based rendering.

2. Ripped or Torn Barcodes

Prevent physical damage by printing barcodes on durable, tear-resistant materials or using protective overlays like laminates.

If barcodes are being torn during handling, consider repositioning them on packaging or documents to avoid stress points.

For essential applications, use redundant barcode placement (e.g., multiple copies on different sides of the packaging) to ensure at least one survives intact.

3. Small Barcode Size

If your barcode is too small to scan consistently, increase the X-dimension (the width of the narrowest bar) to meet minimum scanner specifications.

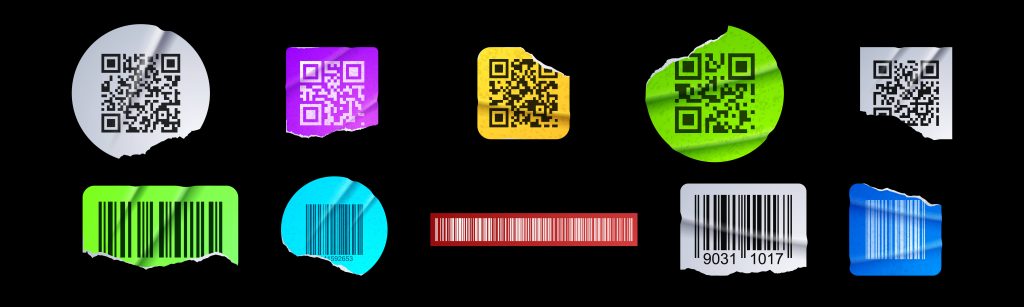

Use high-resolution printing and avoid resizing barcodes after generation, as this introduces distortion. When space is tight, switch to 2D barcodes like QR or Data Matrix, which can hold more data in a compact space and remain readable even at smaller sizes.

4. Dirty or Worn Barcodes

Use smudge-resistant labels and apply them only on clean, dry surfaces to minimize wear and dirt buildup.

For high-contact environments, consider protective films or place barcodes in recessed areas to shield them.

Train your staff to routinely inspect and clean barcode surfaces, and use barcode scanners with image correction features that can handle moderate wear.

5. Printing Errors

Verify that your printer is calibrated correctly, with consistent ink or toner levels and no clogged nozzles.

Use dedicated barcode printing software or libraries that render barcodes accurately without distortion.

Avoid scaling, rotating, or compressing barcode images post-generation, and always print test pages before large batches to catch formatting issues early.

6. Environmental Factors

To mitigate glare and lighting issues, use matte or non-reflective labels and avoid placing barcodes near reflective surfaces.

In cold, humid, or hot environments, opt for specialized label materials rated for those conditions. Also, test scanners under actual working conditions to ensure consistent performance in real-world settings.

7. Scanner or Printer Issues

Keep scanners clean—dust or smudges on lenses can significantly degrade performance. Make sure your scanner’s firmware is up to date and configured to handle the barcode type and resolution you’re using.

If printing is the issue, regularly maintain and clean your printers, and ensure they’re compatible with barcode fonts and formats to avoid misalignment or rendering problems.

How to Fix a Blurry Barcode without Manual Fixes

In many of these barcode issues—whether it’s blurry prints, damaged labels, or inconsistencies from scanning devices—manual fixes can only go so far.

While improving print quality, repositioning labels, and cleaning equipment help reduce errors, they don’t address the root problem: barcode data extraction relies heavily on how intelligent your scanning software is.

This is where using a robust Barcode Scanner SDK, like the one we offer by GdPicture, can make a significant difference to your operations, so worth to evaluate it.

Rather than depending solely on physical conditions being perfect, GdPicture’s SDK leverages advanced image processing and error correction techniques to interpret even low-quality, skewed, or partially damaged barcodes.

It supports over 20 barcode types, including both 1D and 2D formats, ensuring flexibility across use cases.

The SDK also includes features like auto-rotation, deskewing, contrast correction (50+ features) —automatically enhancing barcode readability at the software level, even when physical prints fall short.

For developers integrating scanning into their applications, this means fewer failed scans, less user frustration, and more reliable data capture at scale.

By embedding GdPicture’s barcode capabilities directly into your workflow—whether in document processing, inventory systems, or packaging operations—you reduce dependency on perfect printing or scanner settings.

Instead of reacting to scanning issues, you’re building a system that anticipates and corrects them in real time.

Of course, you might not have a need for it right now, so it might make sense to just review it for now and you can consider it in future when you’re ready.

Conclusion

Blurry barcodes aren’t just a minor inconvenience—they can lead to data errors, delays, and operational inefficiencies if not addressed properly.

Manual fixes like improving print quality, using better materials, and maintaining scanners can go a long way in reducing scan failures.

For a more reliable and scalable solution, consider using a Barcode Scanner SDK, which can intelligently handle poor-quality or a blurry barcode through advanced image processing.

FAQs

Q1. What are the main causes of blurry barcodes? Blurry barcodes typically result from inadequate print resolution, poor printer calibration, environmental factors like moisture and temperature extremes, and physical damage from handling. Addressing these issues requires proper printer maintenance, appropriate label materials, and protective measures.

Q2. How can I improve the quality of printed barcodes? To improve barcode quality, optimize printer settings by adjusting darkness levels, print speed, and printhead pressure. Regularly clean and maintain your printer’s printhead to ensure consistent output.

Q3. What steps can be taken to improve the scanning of existing blurry barcodes?

For existing blurry barcode, using advanced barcode scanning software that can decode difficult or damaged codes is beneficial. Adjusting scanner settings, such as enabling blurry recognition features, and ensuring proper lighting conditions can enhance scanning accuracy. If blurriness persists, consider reprinting the barcodes with improved quality.

Q4. How effective are modern solutions for fixing barcode issues? Modern solutions for barcode issues have proven highly effective. Case studies show that implementing comprehensive technical solutions can reduce scan failures by up to 95% in several industries, eliminate tracking errors, etc.

Q5. What types of barcodes can the GdPicture.NET Barcode Scanner SDK read and write? The Barcode SDK supports a wide range of barcode symbologies, including: 2D Barcodes: Formats like QR Code (including Micro QR Code), Data Matrix, PDF417, Aztec Code, and MaxiCode. 1D Barcodes: Over 30 types, such as Code 39, Code 128, EAN-13, EAN-8, UPC-A, UPC-E, Interleaved 2 of 5, and Codabar

Q6. Which image and document formats are compatible with the SDK for barcode processing? The GdPicture.NET SDK can read and write barcodes in over 100 different image and document formats, including Bitmap, Metafile, and PDF.

Q7. How does the SDK handle blurry barcode or low-quality or skewed images? The SDK employs advanced error correction mechanisms and image processing algorithms to accurately detect and decode barcodes, even in low-quality or skewed images.

Q8. Is the SDK optimized for high-performance and multi-threaded applications? Yes, the GdPicture.NET Barcode Scanner SDK is designed for high-speed scanning and is optimized for performance. It supports AnyCPU configurations, making it available in both 32-bit and 64-bit versions, and is thread-safe, allowing seamless integration into multi-threaded applications.

As CEO, Jonathan defines the company’s vision and strategic goals, bolsters the team culture, and steers product direction. When he’s not working, he enjoys being a dad, photography, and soccer.

Tags: