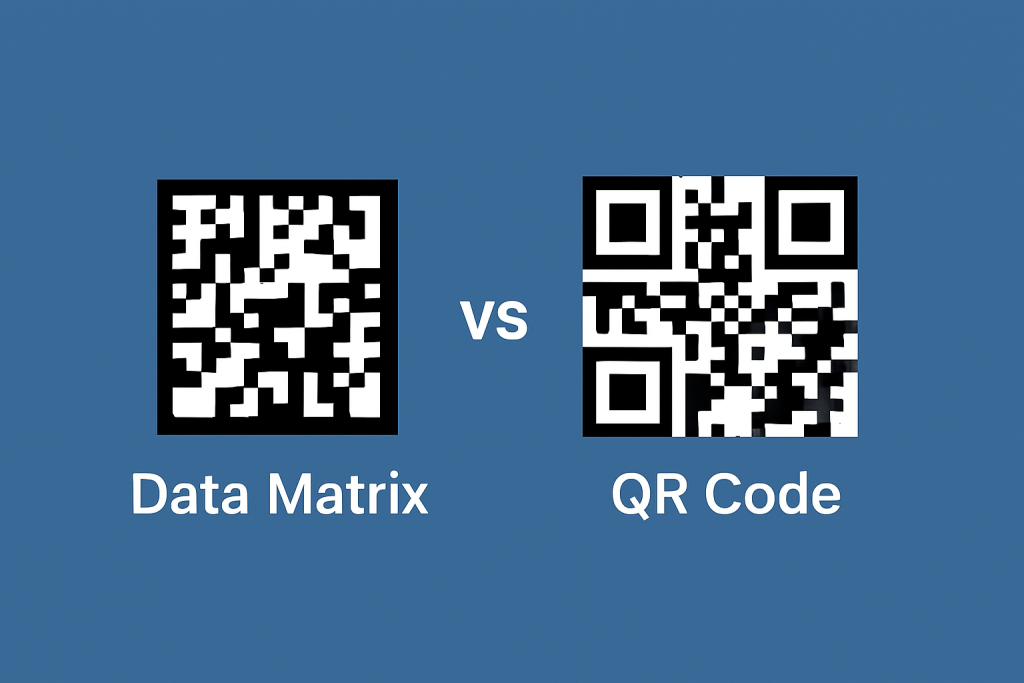

Data Matrix vs QR Code: Key Difference and When to Use Each

Barcodes are foundational to digital traceability, but when it comes to selecting between Data Matrix vs QR code, the decision is more than aesthetic—it’s operational.

Each has unique advantages depending on the application environment, data volume, physical constraints, and long-term durability.

This article shows the differences between Data Matrix and QR codes with a lens on industrial use cases, robustness, which one is right for you, encoding capacity, and standards compliance.

1. 2D Codes: Why Format Matters

While 1D barcodes remain widespread, they are linear and space-inefficient. In contrast, 2D codes like Data Matrix and QR codes encode data both horizontally and vertically, achieving higher density in a smaller footprint.

This is particularly useful in:

- High-speed manufacturing lines

- Micro-marking on surgical or automotive parts

- Smart packaging with embedded digital instructions

Data Matrix and QR codes are the two most used 2D formats. Despite visual similarities, they diverge in how they handle encoding, error correction, durability, and suitability for certain industries.

2. Visual and Technical Specifications

| Feature | Data Matrix | QR Code |

|---|---|---|

| Shape | Square or rectangular | Always square |

| Size efficiency | High (smaller modules) | Medium (larger modules) |

| Encoding capacity | ~2,335 alphanumeric chars | ~4,296 alphanumeric chars |

| Error correction | Up to 30-50% | Up to 30% (L, M, Q, H levels) |

| Space utilization | Excellent | Moderate |

| Scanning speed | Faster for small sizes | Better at larger sizes |

| ISO standard | ISO/IEC 16022 | ISO/IEC 18004 |

Both are public domain and GS1-compliant, but Data Matrix codes are better optimized for limited-space industrial components.

3. Encoding Efficiency and Data Capacity

QR codes can hold more data overall, but they require more physical space to do so. Data Matrix codes, in contrast, can achieve similar results with fewer modules due to their non-linear data mapping and compact module layout.

- Data Matrix: Best when space is a constraint (e.g., electronic chips, bolts, surgical tools).

- QR Code: Better for consumer-facing uses where space is not critical.

For example:

A Data Matrix with 144 x 144 modules can hold 2,335 alphanumeric characters, while a similarly sized QR code needs 177 x 177 modules to hold 4,296 characters—almost 50% more physical space.

4. Durability and Error Resilience in Harsh Environments

In manufacturing, codes face wear from:

- Chemical exposure

- Abrasion

- Heat

- Dust and oil

Data Matrix codes use Reed–Solomon error correction and have proven effective even when up to 50% of the code is degraded.

“We’ve tested laser-engraved Data Matrix codes that remained scannable after 1,000+ cycles in a thermal chamber at 90°C,” said a senior reliability engineer at an aerospace supplier.

QR codes max out at 30% damage tolerance, and the larger size makes them more vulnerable to environmental degradation.

5. Use Cases by Industry

| Industry | Preferred Code | Reason |

|---|---|---|

| Aerospace | Data Matrix | Compact, permanent marking on small parts |

| Medical Devices | Data Matrix | Traceability, ISO compliance, survives autoclave sterilization |

| Consumer Goods | QR Code | High data needs (e.g. links, promotions), scannable by smartphones |

| Logistics | Both | Depends on label size and environment |

| Automotive | Data Matrix | DPM compatibility, high-speed scanning |

| Retail | QR Code | Marketing, payment systems, mobile engagement |

In regulated sectors, Data Matrix is preferred due to support for direct part marking (DPM) and robust traceability compliance (e.g., FDA, DoD, ISO 15459).

6. Implementation and Marking Techniques

A. Marking Methods

| Marking Method | QR Code Compatible | Data Matrix Compatible | Durability |

|---|---|---|---|

| Printed Label | ✅ | ✅ | Low |

| Laser Marking | ⚠️ (size limits) | ✅ | High |

| Dot Peen Marking | ❌ | ✅ | Medium |

| Inkjet Printing | ✅ | ✅ | Low |

Data Matrix is the only 2D code readable when dot-peened or laser-etched at small scales. QR codes require more real estate and struggle with low-contrast surfaces.

B. Best Practices for Implementation

- Apply marks in areas sheltered from mechanical wear

- Validate with ISO/IEC 15415 (symbol quality) and 29158 (DPM quality)

- Use verifiers during production, not just scanners

7. Regulatory Compliance and Standards

Both codes are GS1- and ISO-approved, but only Data Matrix codes are required by certain standards:

| Standard | Requires Data Matrix | Accepts QR Code |

|---|---|---|

| GS1 UDI (Healthcare) | ✅ | ⚠️ (optional) |

| MIL-STD-130 (Defense) | ✅ | ❌ |

| ISO/IEC 15459 (Traceability) | ✅ | ✅ |

According to the U.S. FDA, “Unique Device Identification (UDI) systems must incorporate Data Matrix codes on Class II and III medical devices.”

This makes Data Matrix a compliance-driven choice in regulated fields.

8. Cost, Scalability, and Ecosystem

From a cost perspective:

- QR code generation and scanning are supported widely on mobile and consumer-grade hardware.

- Data Matrix codes require more specialized hardware for laser marking and industrial scanning—but cost per unit is negligible at scale.

Ecosystem Considerations

| Attribute | QR Code | Data Matrix |

|---|---|---|

| Smartphone scan support | ✅ Universal | ❌ Limited |

| Supply chain systems | ✅ Supported | ✅ Preferred |

| Integration APIs | ✅ Abundant | ✅ Abundant |

| Customization options | ✅ High (logo, color) | ⚠️ Low |

For B2C use cases, QR wins. For B2B, regulatory, or embedded systems, Data Matrix is favored.

9. Data Matrix vs QR Code — When to Choose Which

Let us give you 2 simple comparison tables based on your decision factor and also on different features –

| Decision Factor | QR Code | Data Matrix |

|---|---|---|

| Consumer scanning | ✅ | ❌ |

| Limited marking space | ❌ | ✅ |

| Harsh industrial settings | ❌ | ✅ |

| High-volume traceability | ⚠️ | ✅ |

| Flexible design options | ✅ | ❌ |

| Direct part marking (DPM) | ❌ | ✅ |

| Regulatory compliance | ⚠️ | ✅ |

Feature QR Code Data Matrix Common Use Cases Consumer apps, URLs, payments Industrial labels, tiny components Size Efficiency Requires more space at large sizes Better for small areas Error Correction Stronger (up to 30% with Reed-Solomon) Basic (ECC 200) Orientation Handling Excellent Excellent Read Speed (in SDK) Very fast Very fast ROI Support (in SDK) Yes Yes “In industrial applications where a part may be subjected to harsh environments or must be uniquely identified over decades, Data Matrix is the standard,” notes an industrial automation consultant at Siemens.

10. What Data Matrix and QR Codes Have in Common

Before diving into their differences, it’s important to recognize their similarities—especially when using GdPicture:

- Both are fully supported for scanning and generation

- GdPicture exposes dedicated methods for each format

- You can extract barcode values, position data, confidence levels, and other format-specific properties

- Coordinates are relative to the Region of Interest (ROI) if one is defined

With the SDK, handling both formats in .NET applications becomes seamless.

11. Where is Data Matrix Used

Data Matrix is often used in manufacturing, pharmaceuticals, and logistics where high-density barcodes are required on small surfaces.

Key Features in GdPicture SDK:

- Scanning Methods:

BarcodeDataMatrixReaderGetBarcodeValue()– returns the barcode’s decoded valueBarcodeDataMatrixReaderGetBarcodeValueRAW()– returns the raw binary contentBarcodeDataMatrixReaderGetBarcodeSkewAngle()– determines how skewed the barcode isBarcodeDataMatrixReaderGetBarcodeRows()– returns the number of rows in the symbol

- Position Information:

X1,X2,X3,X4, andY1,Y2– corner positions of the detected barcode- These are relative to the ROI, if one is set

Data Matrix is ideal for environments where printing space is limited, or where barcodes need to survive harsh conditions (e.g., laser-etched codes on metal).

12. Where is QR Code Used

QR Codes are more consumer-facing and are frequently used in marketing, mobile apps, retail, and payments.

Key Features in GdPicture SDK:

- Scanning Methods:

BarcodeQRReaderGetBarcodeValue()– decodes the stringBarcodeQRReaderGetBarcodeValueRAW()– gets raw binary dataBarcodeQRReaderGetVersion()– returns the QR version (from 1 to 40)

- Position Coordinates:

X1,X2,X3,X4,Y1,Y2,Y3,Y4– defines the full boundary of the code- Also ROI-relative, enabling focused scanning in defined zones

QR Codes have built-in error correction, which makes them resilient in real-world usage—even when partially damaged or obscured.

13. Barcode Generation with GdPicture

GdPicture also supports barcode creation for both formats, making it easy to embed barcodes into PDFs, labels, or documents.

You can define:

- Encoding type (ASCII, UTF-8, etc.)

- Size and resolution

- Error correction level (for QR)

- Quiet zone / margin

This enables you to build complete barcode workflows—from creation to scanning—all in one SDK.

Conclusion and Key Takeaways

The choice between Data Matrix vs QR code isn’t about which one is better in general—it’s about which is fit for purpose. For smartphone-based interaction and marketing, QR codes offer unmatched reach. But for industrial-grade identification, traceability, and compliance, Data Matrix is the tool of choice.

The best strategy is to align your barcode system with operational goals—from the shop floor to the supply chain to the end user. Whether you’re marking automotive pistons or launching product-based AR experiences, the right 2D code ensures efficiency, resilience, and traceability.

Whether you’re embedding barcodes into a manufacturing process or scanning QR codes from mobile apps, GdPicture’s barcode SDK provides reliable, fast, and flexible tools for working with both Data Matrix and QR Code formats.

Instead of choosing one over the other, the real power lies in understanding when to use each format—and how to implement both cleanly with the SDK.

Start scanning and generating barcodes with GdPicture’s Barcode SDK. If you have any specific requirements, contact our sales team to book a demo.

FAQs

What is the main difference between Data Matrix vs QR Code?

Data Matrix is designed for compact, high-density marking—ideal for small items in industrial or medical environments. QR Code is more common in consumer-facing applications and supports higher error correction.

Does GdPicture support scanning and generating both barcode types?

Yes. GdPicture fully supports both Data Matrix and QR Code for reading and generation. Each format has its own dedicated methods in the SDK to handle values, coordinates, and metadata.

Can I scan barcodes within a specific region using GdPicture?

Yes, both Data Matrix and QR Code methods support scanning relative to a defined Region of Interest (ROI), helping you target specific parts of an image or document.

Which barcode type should I use for very small labels?

Data Matrix is better suited for small labels because of its ability to encode information in a tighter space, even when printed at low resolution or etched on metal.

How do I retrieve the version of a QR Code with GdPicture?

Use the method BarcodeQRReaderGetVersion() to get the version number of the scanned QR Code, which reflects its data capacity and matrix size.

Hulya is a frontend web developer and technical writer at GDPicture who enjoys creating responsive, scalable, and maintainable web experiences. She’s passionate about open source, web accessibility, cybersecurity privacy, and blockchain.

Tags: